Aquarium controller using ESP8266 platform, created for my dad, Featuring 2x20 LCD, web portal over Wi-Fi, lights controls with day schedule and smooth transitions, water conditioning, refilling and circulation, micro-elements dosing (pumps), temperature and pH sensors with calibration and cloud logging.

- Summarized status display on 2x20 LED.

- Portal website hosted over Wi-Fi with status and configuration.

- Lights controls with day schedule configuration and smooth transitions.

- Water conditioner, with heating/cooling controller by thermometer.

- Water level detection and refilling.

- Simple circulator controller (periodical)

- Dosing minerals/micro-elements with pumps.

- Water pH (acidity/basicity) meter (PH-4502C).

- Cloud logging of various parameters.

- Most of UI uses Polish language.

Few photos of the aquarium, the setup and the controller. Web application screenshot is also included, more further below.

|

|

||

|

|||

|

|

|

|

Hardware consists of:

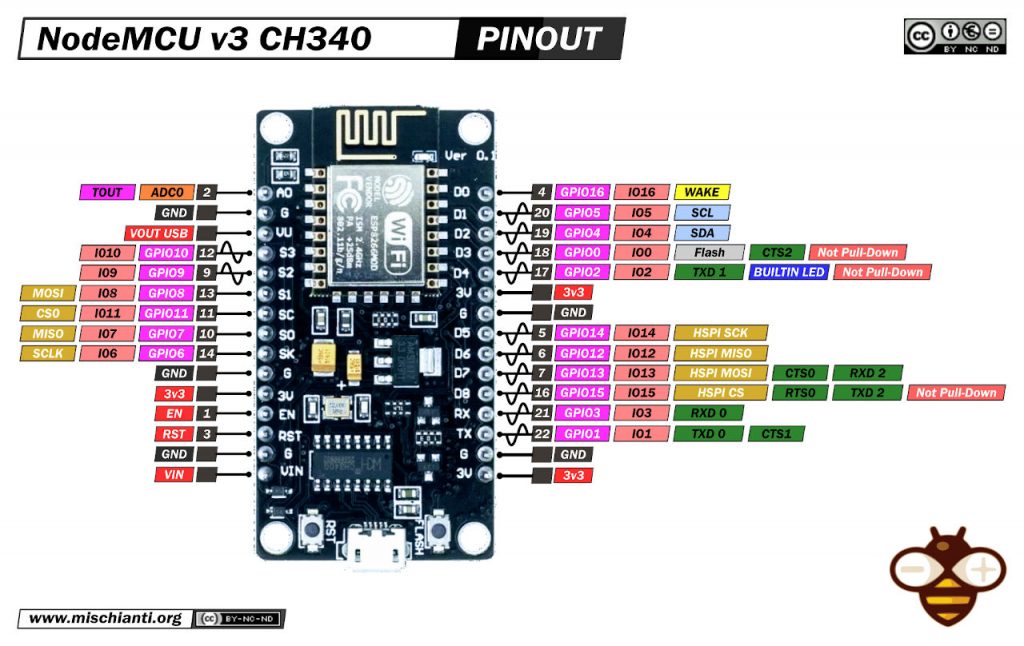

- ESP8266 (NodeMCU ESP-12E) microcontroller.

- 2x20 LCD via I2C.

- PCF8574 digital IO expander.

- DS3231 clock.

- DS18B20 thermometer (via OneWire).

- More on-board specific electronics (incl. relays, transistors, passives).

...

| Pinout name | Pin in code | Mode | Type | Designation | Notes |

|---|---|---|---|---|---|

| A0 | ADC0 | Input | Analog | Water ph meter | |

| S3 | 10 | ? | PWM | Free | Free. |

| S2 | 9 | ? | PWM | Free | Free. |

| S1 | 8 | ? | PWM | Free | Free. |

| SC | 11 | ? | PWM | Free | Free. |

| SO | 7 | ? | PWM | Free | Free. |

| SK | 6 | ? | PWM | Free | Free. |

| D0 | 16 | ? | Digital | Water cooling | Wake/sleep unusable anymore. |

| D1 | 5 | Special | Digital | SCL (I2C) | |

| D2 | 4 | Special | Digital | SDA (I2C) | |

| D3 | 0 | ? | Digital | Free | Free, flash. |

| D4 | 2 | Special | Digital | OneWire / Built-in LED | Used by DS18B20 thermometer. |

| D5 | 14 | Output | PWM | White LEDs | |

| D6 | 12 | Output | PWM | Blue LEDs | |

| D7 | 13 | Output | PWM | Red LEDs | |

| D8 | 15 | Output | PWM | Green LEDs | |

| RX | 3 | Special | Digital | Serial read | |

| TX | 1 | Special | Digital | Serial transmit | |

| Pin | Mode | Designation | Notes |

|---|---|---|---|

| 0 | Output | Water heating | LOW if heating. |

| 1 | Output | Water refilling | LOW if refilling. |

| 2 | Output | Minerals pump - Ca | LOW when pumping. |

| 3 | Output | Water circulator | LOW when active. |

| 4 | Output | Minerals pump - KH | LOW when pumping. |

| 5 | Output | Minerals pump - Mg | LOW when pumping. |

| 6 | Input | Water level detection | HIGH if low level. |

| 7 | Input | Backup water tank level detection | HIGH if low level. |

-

While connecting to Wi-Fi:

.--------------------. |SSID: AAAAAAAAAAAAAA| <-- SSID being displayed. |IP: * - * - * - * - | <-- IP is not know yet, animation is displayed. '--------------------' -

After connected, until IP showing timeout or anyone connected to web portal:

.--------------------. |HH:mm:ss TT.T^C| <-- Time and water temperature. |IP: AAA.BBB.CCC.DDD| <-- IP used by the controller. '--------------------' -

Running:

.--------------------. |HH:mm:ss @@ TT.T^C| <-- Time, WiFi status and water temperature or water pH level. |Message here... G| <-- Custom message (like pumping in progress) and 'G' set or hidden whenever heating is on. '--------------------'.--------------------. |HH:mm:ss AP pH 7.1| |Message here... G| '--------------------'

Platform IO is used with Arduino framework for development.

- Web server,

- Network code (connect to configured network, incl. IP configuration; or host AP)

- Lights controller,

- Water temperature controller (heating/cooling),

- Circulator controller,

- Cloud logging controller,

- Minerals pumps controller,

- Water refilling controller,

Web content (web directory) is prepared by prepareWebArduino.js script into src/webEncoded as compressed, allowing easy embedding in web server code with simple macros.

| Request | Description |

|---|---|

/status |

Returns JSON with status object. |

/config (?=...) |

Updates config values (from query params) and/or returns JSON with current config. |

/saveEEPROM |

Saves any config and persistent data (incl. colors cycles) to EEPROM. |

/getColorsCycle |

Returns JSON with colors cycle object. |

/setColorsCycle (POST) |

Updates colors cycle from encoded value send via POST (see sources for details). |

/resetColorCycle |

Resets colors cycle to defaults. |

/mineralsPumps (?=...) |

Allows for minerals pumps controlling (handy for calibration) and returns run time info. |

Reports status.

Returns:

{

"waterTemperature": 22.01,

"rtcTemperature": 22.25,

"phLevel": 7.1234,

"phRaw": 1024,

"red": 0,

"green": 127,

"blue": 255,

"white": 0,

"heatingStatus": 2,

"isRefilling": false,

"isRefillTankLow": false,

"timestamp": "2022-03-13T16:01:17",

"rssi": -67

}Allow changing configuration via passed arguments in query.

Arguments (should be joined with & to form querystring):

timestamp=2004-02-12T15:19:21

red=255

green=255

blue=255

white=255

forceColors=true

waterTemperatures.minimal=22.50

waterTemperatures.optimal=24.00

waterTemperatures.maximal=25.50

circulatorActiveTime=10

circulatorPauseTime=5

mineralsPumps.ca.time=570

mineralsPumps.ca.mL=10

mineralsPumps.ca.c=412.000

mineralsPumps.mg.time=570

mineralsPumps.mg.mL=10

mineralsPumps.mg.c=420.310

mineralsPumps.kh.time=570

mineralsPumps.kh.mL=10

mineralsPumps.kh.c=397.016

phMeter.points.0.adc=712

phMeter.points.0.pH=9.20

phMeter.points.1.adc=851

phMeter.points.1.pH=6.88

phMeter.points.2.adc=1008

phMeter.points.2.pH=4.03

network.mode=2

ssid=Hotspot

psk=12345678

static=1

ip=192.168.1.123

mask=24

gateway=192.168.1.1

dns1=1.1.1.1

dns2=1.0.0.1

cloudLoggingInterval=10

Returns:

{

"waterTemperatures": {

"minimal": 22.50,

"optimal": 24.00,

"maximal": 25.50

},

"circulatorActiveTime": 10,

"circulatorPauseTime": 10,

"mineralsPumps": {

"ca": { "time": 570, "mL": 10 },

"mg": { "time": 570, "mL": 10 },

"kh": { "time": 570, "mL": 10 }

},

"phMeter": {

"points": [

{ "adc": 800, "pH": 7.11 },

{ "adc": 800, "pH": 7.11 },

{ "adc": 800, "pH": 7.11 }

],

"adcMax": 1024,

"adcVoltage": 3.2

},

"network": {

"mode": 2,

"ssid": "Hotspot",

"psk": "12345678",

"static": 1,

"ip": "192.168.55.249",

"mask": 24,

"gateway": "192.168.55.1",

"dns1": "192.168.55.1",

"dns2": "1.1.1.1"

},

"cloudLoggingInterval": 10,

}0x26- Digital IO expander (PCF8574)0x27- LCD0x57- DS3231 Memory?0x68- DS3231 RTC

Size: 0x1000 (4kB), used 0x200 (512b).

-

0x000-0x020- Empty header & checksum.0x01C-0x020- CRC32 checksum.

-

0x020-0x030- Water temperature.0x020-0x024(float) - Minimum temperature (lowers starts heating).0x024-0x028(float) - Optimal temperature (stops heating or fans).0x028-0x02C(float) - Maximal temperature (above starts fans).

-

0x030-0x040- Water circulation.- 1 byte - Circulator active time start (hour number).

- 1 byte - Circulator active time start (minute number).

- 1 byte - Circulator active hours end.

- 1 byte - Circulator active hours end.

- 4 bytes - Circulator active period in milliseconds.

- 4 bytes - Circulator pause period in milliseconds.

-

0x040-0x060- pH meter settings (calibration).0x040,0x044,0x048,0x04C,0x050(5xfloat) - Defined pH levels.0x054,0x056,0x058,0x05A,0x05C(5xu16) - ADC readings for defined levels.0x05E(u8) - Number of points.0x05F(u8) - Interpolation method selection enum.

-

0x060-0x080- Minerals pumps settings.Format:

- 4 bytes - calibration float.

- 1 byte - hour number (pump disabled if outside of 0-24).

- 1 byte - minute number.

- 1 byte - millimeters dose (so max dose is 250-255mL).

- 1 byte padding (to round up at 8 bytes).

Three pumps, total of 24 bytes.

-

0x080-0x100- Smooth light controller entries.Entry format:

- 1st byte - hour

- 2nd byte - minute

- 3rd byte - red light PWM value

- 4th byte - green light PWM value

- 5th byte - blue light PWM value

- 6th byte - while light PWM value

- 2 bytes padding (round up to 8 bytes).

It means there are

16customizable entries. -

0x100-0x160- Some network settings.Some SSID, PSK and some mode specific settings are saved internally by SDK, therefore not included here. IPv4 fields: 192.168.4.1 == 0x0104A8C0.

- 1 byte - mode/flags (disabled/always ap/station/fallback ap; whenever to use static ip or not).

- 4 bytes - IPv4 for device.

- 4 bytes - Network mask.

- 4 bytes - Gateway IP.

- 4 bytes - IPv4 for DNS 1.

- 4 bytes - IPv4 for DNS 2, or 0 if none.

- 8 bytes of padding.

- 64 bytes - basic authorization token, encoded (base64 of

login:password).

-

0x160-0x200- Cloud settings.- 16 bytes - secret, to authorize and/or identify the controller (needs to end with \0).

- 4 bytes - interval for cloud logger (in milliseconds).

- 12 bytes padding.

0x180-0x200- cloud endpoint URL.

There is HTTPS client running every configured interval sending the request with readings sample to endpoint. As the endpoint, Google Apps Script with POST handler is used. On this repository it's code should be stored in cloud/ folder. Data is stored into Google Spreadsheet document.

-

Fix water level refilling

crashresets time!- Most likely it's fixing hardware issue (electromagnetic interference) with software, but fuck it :P

- Hardware fixing will be attempted too I hope :COPIUM:

- Current fix with delays before/after pump I/O switching isn't full solution, just slicing the chance down.

- Try save time before running pump and then update it after (with added offset) if the time was reset.

- Use NTP simple client to sync time if anything happens.

- Try keep track of time even without the DS3221 (which gets corrupted in this scenario)

- Could include milliseconds that way, would prove useful for smoother LED transitions.

- Maybe would be even a bit faster, no holding the I2C I/O for every time read.

- Might want to rewrite DS3221 library to do all this cleanly.

- Can't really work after restarting offline without it.

- Allow to start without it if there is internet access.

- Option to allow to start without time at all, a bit unsafe, but better than nothing in edge scenario.

-

Rewrite water refilling code, why have I used shifting registers instead counting again?

-

Prevent pump running endlessly when no water in either of tanks.

-

Include more stuff on the cloud log

Uptime(done, but would roll over at )Memory usage, free heap, heap fragmentation- Water refill pump

- Minerals pumps

- Heating/cooling

- Circulation (?)

- Separate pushes?

- Keeping track of last start timers?

-

Cloud logger buffer (configurable; in such case charts could get data from status too?).

-

Charts/cloud need major rewrite

- Avoid fetching all data at once, browsers can't handle too much points.

- Calendar

- Allow to select dates range to show on slider.

- Singular request (singular table with newest row being updated)

- Show summary stats (min/max/avg for water temperature and pH, etc) per day.

- Slider

- Allow to move detailed view across dates selected in calendar.

- Use points from averaged data to create mini-graph preview to slide on.

- Allow move the slider view/window by buttons on left and right.

- Detailed view (with all points, fetching on demand)

- Cloud storage notes:

- Google Sheets/Scripts as cloud :P

- Each month in separate table/sheet.

- Each month has per day summary (30+ records), her hour summary (720+ records) and lastly, the raw data.

- Assuming 30 second interval for reports, 100 MB should be enough for a month.

- Make the view usable on mobile

- Rotate!

- Option to auto-scale to represent the data in detailed view with more accuracy.

- Show/hide system package temperature, to keep it away from messing with auto-scaling on temperatures scale.

- (OLD) Chart link/button for last hour/day should show error if no data to show.

- (OLD) Add loading/error information for line charts.

- Include cloud endpoint code (Google App Scripts) here.

-

Use UDP for cloud logging? Trying to cut down time required to upload.

-

Try logging crashes to cloud?

-

Split README into pieces, use

docs/folder, keep README for nice project summary.- Maybe try to create electronics schematic? A bit backlogging, hard to do now when it's alive.

-

Store cloud logger settings in EEPROM (incl. URL and secret) (already in EEPROM structure, but unused).

-

WiFi settings graying out if DHCP is used and show mask as IP.

-

Make

/configendpoint use proper GET/POST to avoid lag of printing so much when only setting. -

Make

/colorsCycleendpoint instead separateset/get. RESTful somewhat, GET/POST. -

RESTful API (see https://arduinojson.org/ or https://github.com/cesanta/mjson)

-

Write rest of API docs.

-

Optional color slider transformation (illusion of control, first parts of slider affect lesser part of raw value).

-

UI for WiFi settings for AP (SSID/password/channel/hidden).

-

Safe WiFi reconnecting and device restarting - pumps might be running!

-

Add circulator night mode, with settable hour:minute (already in EEPROM structure, but unused).

-

Add feeding mode - circulator disable (and maybe special lighting?)

-

Try soft-PWM on io expander (rapid switching? https://www.youtube.com/watch?v=Fsb7kxDxYGw http://sim.okawa-denshi.jp/en/PWMtool.php).

-

Circulator force run button.

-

Extend RTC with milliseconds (sync on start and use

millis); Use extended RTC for smoother LEDs transitions. -

Add fancy animations on demand for LEDs.

-

Show total running time (from last power-on), under current time at web portal.

-

Try overclock ESP into 160 MHz.

-

Use better web server library (https://github.com/me-no-dev/ESPAsyncWebServer).

-

Make sure no strings are created (allocated) when handling request - allocate them in advance if necessary.

-

Use HTTPS for web server.

-

Use some authorization for web panel config setting.

-

Reuse light cycle 2 bytes instead of hour/minute start/stop bytes for things like pumps or circulator.

-

Add polynomial/Newton interpolation for calculating ph level.

-

Temperature compensation for ph calculation.

-

Don't remove unchanged files at

prepareWebArduino(support directory tree). -

Add

--watchtoprepareWebArduino. -

Exportable/importable colour cycle configuration (as JSON/encoded?) .

-

Saving/reading colour cycle presets from browser storage.

-

Refactor DS3231 library (lighter one, use full DS3231 instead pieces).

-

Use

mimetable.cppfor MIME types? No. Not until ESP8266 core impl fixes 3-4 times copying. Also,getContentTypeis copying even more XD. -

Standard Arduino/ESP core libraries are bad... I want to do better, but shitty foundations make it futile or too hard.

- Stream using int instead char?

- Lack or invalid comments.

- Inconsistent namings.

- Formatting even worse than C++ STD.

- Paying for unused features.

-

Use

snprintf_Pin place ofsnprintf? SRAM is faster than PROGMEM tho.