Nonlinear plate dynamics analysis based on FEM shell element with Absolute Nodal Coordinate Formulation (ANCF) 1. (This code is validated with MATLAB R2007b or later versions)

Communication

Language

├─Plate_FEM_explicit_3_SURFplot

│ ├─cores

│ │ ├─functions

│ │ ├─solver

│ │ └─ToolBoxes

│ └─save

│ └─fig

└─Plate_FEM_implicit_0

├─cores

│ ├─functions

│ ├─solver

│ └─ToolBoxes

└─save

└─fig

-

Plate_FEM_implicit_0 : Implicit solver (Faster and more robust under the thin thickness condition)

-

Plate_FEM_explicit_3_SURFplot : Explicit solver (Light computing cost)

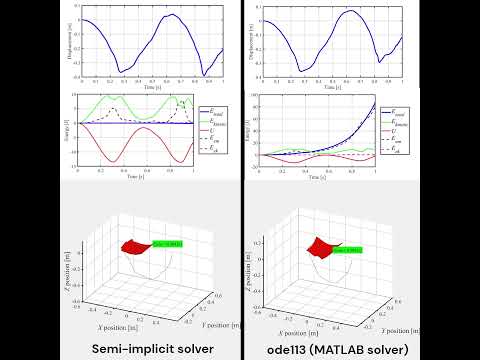

Comparisons between Semi-implicit solver vs ODE113 (MATLAB explicit solver)

This code with the implicit solver (Plate_FEM_implicit_0) was employed as a structure solver for the following publication(s):

- Influence of the aspect ratio of the sheet for an electric generator utilizing the rotation of a flapping sheet, Mechanical Engineering Journal, Vol. 8, No. 1 (2021).

https://doi.org/10.1299/mej.20-00459

@article{Akio YAMANO202120-00459,

title={Influence of the aspect ratio of the sheet for an electric generator utilizing the rotation of a flapping sheet},

author={Akio YAMANO and Hiroshi IJIMA and Atsuhiko SHINTANI and Chihiro NAKAGAWA and Tomohiro ITO},

journal={Mechanical Engineering Journal},

volume={8},

number={1},

pages={20-00459-20-00459},

year={2021},

doi={10.1299/mej.20-00459}

}

- Flow-induced vibration and energy-harvesting performance analysis for parallelized two flutter-mills considering span-wise plate deformation with geometrical nonlinearity and three-dimensional flow, International Journal of Structural Stability and Dynamics, Vol. 22, No. 14, (2022).

https://doi.org/10.1142/S0219455422501632

@article{doi:10.1142/S0219455422501632,

author = {Yamano, Akio and Chiba, Masakatsu},

title = {Flow-Induced Vibration and Energy-Harvesting Performance Analysis for Parallelized Two Flutter-Mills Considering Span-Wise Plate Deformation with Geometrical Nonlinearity and Three-Dimensional Flow},

journal = {International Journal of Structural Stability and Dynamics},

volume = {22},

number = {14},

pages = {2250163},

year = {2022},

doi = {10.1142/S0219455422501632}

}

- Influence of boundary conditions on a flutter-mill, Journal of Sound and Vibration, Vol. 478, No. 21 (2020).

https://doi.org/10.1016/j.jsv.2020.115359

@article{YAMANO2020115359,

title = {Influence of boundary conditions on a flutter-mill},

journal = {Journal of Sound and Vibration},

volume = {478},

pages = {115359},

year = {2020},

doi = {https://doi.org/10.1016/j.jsv.2020.115359},

author = {A. Yamano and A. Shintani and T. Ito and C. Nakagawa and H. Ijima}

}

[Step 1] Install the ToolBoxes

The following ToolBoxes in “./XXXX/cores/ToolBoxes/” are required,

For numerical analysis:

- “Meshing a plate using four noded elements” by KSSV:

https://jp.mathworks.com/matlabcentral/fileexchange/33731-meshing-a-plate-using-four-noded-elements

- “Sparse sub access” by Bruno Luong:

https://jp.mathworks.com/matlabcentral/fileexchange/23488-sparse-sub-access

- “Vectorized Multi-Dimensional Matrix Multiplication” by Darin Koblick:

For plotting results:

- “mmwrite” by Micah Richert:

https://jp.mathworks.com/matlabcentral/fileexchange/15881-mmwrite

- “mpgwrite” by David Foti:

https://jp.mathworks.com/matlabcentral/fileexchange/309-mpgwrite?s_tid=srchtitle

- “mmread” by Micah Richert:

https://jp.mathworks.com/matlabcentral/fileexchange/8028-mmread

[Step 1.2] Add path to installed ToolBoxes

Modify "add_pathes.m" to add path to abovementined installed ToolBoxes as follows,

addpath ./cores/ToolBoxes/XX;

where XX is the name of folder of the installed ToolBox.

[Step 2] Start GUI form

Open the “GUI.fig” from MATLAB.

[Step 2.1] Pre-setting

Push the "Parameters" button and edit parameters.

[Step 3] Start analysis

Push the “exe” button and wait until the finish of the analysis.

[Step 4] Plot results

Push the “plot” button.

[Step 5] View plotted results

Results (figures and movie) plotted by [Step 4] are in "./save" directory.

Analytical condisions are in "./save/param_setting.m"

End_Time = 1.0; %% Analytical time [s]

d_t = 1e-4; %% step time [s]

core_num = 6; %% The number of CPUs for computing [-]

movie_format = 'mpeg'; %% movie format [-]

% movie_format = 'avi';

speed_check = 0; %%

%% Plate

rho_m = 1000; %% density [kg/m^3]

Eelastic = 1e+3; %% Young's modulus [Pa]

nu = 0.3; %% Poiison ratio [-]

Length = 100e-3; %% Length [m]

Width = 100e-3; %% Width [m]

thick = 10e-3; %% Thickness [m]

Nx = 8; %% The number of x-directional elements [-]

Ny = 8; %% The number of y-directional elements [-]

N_gauss = 5; %% Gauss-Legendre [-]

g = 9.81; %% gravity acc. [m/s^2]

F_in = -rho_m*g*[ 0 0 1].'; %% gravity [N/m^3]

and boundary conditions for nodes on plate;

%% Boundary conditions

node_r_0 = [ 1]; %% Node number for fixed node [-]

node_dxr_0 = [ ]; %% Node number for fixed x-directional gradient [-]

node_dyr_0 = [ ]; %% Node number for fixed y-directional gradient [-]

Then, boundary conditions for a plate are written as,

- Clamped at the leading-edge

%% Boundary conditions

node_r_0 = [ 1:Ny+1 ]; %% Node number giving the displacement constraint [-]

node_dxr_0 = [ 1:Ny+1 ]; %% Node number giving x-directional gradient constraint [-]

node_dyr_0 = [ 1:Ny+1 ]; %% Node number giving y-directional gradient constraint [-]

- Pinned at the leading-edge

%% Boundary conditions

node_r_0 = [ 1:Ny+1 ]; %% Node number giving the displacement constraint [-]

node_dxr_0 = [ ]; %% Node number giving x-directional gradient constraint [-]

node_dyr_0 = [ 1:Ny+1 ]; %% Node number giving y-directional gradient constraint [

where index in vector shows the node index around a plate element to apply boundary conditions.

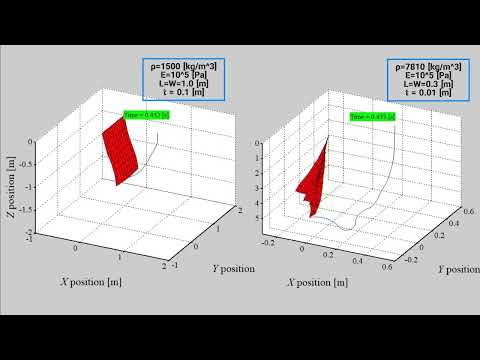

- Young's modulus:

$1.0 \times 10^5 \ \rm{Pa}$ - density:

$7810 \ \rm{kg/m^3}$ - Poisson ratio:

$0.3$ - Length, width:

$0.3 \ \rm{m}$ - Thickness:

$0.01 \ \rm{m}$

Deformed shape of the pendulum by this code (

Deformed shape of the pendulum by this code (

Deformed shape of the pendulum by the preceding report (Model I,

Time series of energy of the falling plate.

MIT License

Issue reports and pull requests are highly welcomed.