-

Notifications

You must be signed in to change notification settings - Fork 460

bladeRF CLI Tips and Tricks

Samples received via the bladeRF-cli, in either CSV or binary format, can easily be imported into tools such as Octave, MATLAB or baudline.

The first step is to open the device and configure it using the bladeRF-cli. The below example configures the device to tune to 1.575.42 MHz, with an 8MHz sample rate and 5 MHz bandwidth. Change these and the gain values as needed.

$ bladeRF-cli -i

bladeRF> set frequency rx 1575.42M

Set RX frequency: 1575420000Hz

bladeRF> set samplerate rx 8M

Setting RX sample rate - req: 8000000 0/1Hz, actual: 8000000 0/1Hz

bladeRF> set bandwidth rx 5M

Set RX bandwidth - req: 5000000 Hz actual: 5000000 Hz

# Automatic gain control is enabled by default with libbladeRF 2.0.0 and later.

# If you wish to disable it and set gains manually:

#

# bladeRF> set agc off

#

# Before libbladeRF 2.0.0, 'set lnagain', 'set rxvga1', and 'set rxvga2' were

# used to individually set the gain stages on the bladeRF x40/x115. With

# libbladeRF 2.0.0 and later, on any bladeRF, 'set gain rx 60' will set maximum

# gain, and values less than 60 will be less than that:

#

# bladeRF> set gain rx 60

bladeRF> print

RX Bandwidth: 5000000 Hz

TX Bandwidth: 28000000 Hz

RX Frequency: 1575420000 Hz

TX Frequency: 1000000000 Hz

GPIO: 0x00000037

LMS Enable: Enabled

LMS RX Enable: Enabled

LMS TX Enable: Enabled

TX Band: Low Band (300M - 1.5GHz)

RX Band: High Band (1.5GHz - 3.8GHz)

RX Source: LMS6002D

Loopback mode: none

RXLNA Gain: 6 dB

RXVGA1 Gain: 30 dB

RXVGA2 Gain: 9 dB

TXVGA1 Gain: -14 dB

TXVGA2 Gain: 0 dB

Sampling: Internal

RX sample rate: 8000000 0/1

TX sample rate: 12000000 0/1

Current VCTCXO trim: 0x9130

Stored VCTCXO trim: 0x9130

Expansion GPIO: 0xf9ff391f

Expansion GPIO direction: 0x00000000 (1=output, 0=input)Next, we receive samples and write them to a file.

When writing large number of samples, especially at higher sample rates, you should use the binary format to save on disk space. Additionally, consider saving samples to a ramdisk or SSD, rather than an HDD.

Below is an example of receiving (20 * 1024 * 1024) samples, using the binary "SC16 Q11" format:

bladeRF> rx config file=my_samples.sc16q11 format=bin n=20M

bladeRF> rx start;

bladeRF> rx

State: Running

Last error: None

File: my_samples.sc16q11

File format: SC16 Q11, Binary

# Samples: 20971520

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000

bladeRF> rx wait

bladeRF> rx

State: Idle

Last error: None

File: my_samples.sc16q11

File format: SC16 Q11, Binary

# Samples: 20971520

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000If you'd like to save samples to a CSV, you can change the format option:

bladeRF> rx config file=my_samples.csv format=csv n=20M

bladeRF> rx start

bladeRF> rx

State: Running

Last error: None

File: my_samples.csv

File format: SC16 Q11, CSV

# Samples: 20971520

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000

bladeRF> rx wait

bladeRF> rx

State: Idle

Last error: None

File: my_samples.csv

File format: SC16 Q11, CSV

# Samples: 20971520

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000Routines for loading/saving samples from/to various formats are provided here in the bladeRF git repository.

The below examples show how to plot the magnitude of samples received in the above example.

In the CSV format, samples are stored in rows of: I, Q.

To load these samples and reconstruct the complex signal:

% We must first tell MATLAB/Octave where to find our functions

% by pointing it to the directory containing the conversion routines.

% You will need to change this path as needed.

addpath('~/projects/bladeRF/host/misc/matlab/')

% Load the samples

signal = load_csv('my_samples.csv');

% Plot the magnitude of the signal in the time domain

plot(abs(signal));

Binary data in the SC16Q11 format is little-endian, sign-extended, and right-aligned. To load the samples and reconstruct the complex signal:

% We must first tell MATLAB/Octave where to find our functions

% by pointing it to the directory containing the conversion routines.

% You will need to change this path as needed.

addpath('~/projects/bladeRF/host/misc/matlab/')

% Load the samples

signal = load_sc16q11('my_samples.sc16q11');

% Plot the magnitude of the signal in the time domain

plot(abs(signal));

Samples must be in a binary format to be used with baudline. This section assumes you've saved them to the binary SC16Q11 format, but other conversions are certainly possible.

Here's one way to view binary samples you've saved off using the bladeRF-cli program. Note that you can open a file using these settings from the command-line as well.

- Open baudline

- Right-click and select Input -> Open File

- Change File Format to raw

- Select your file and click Open

- Set the following parameters in the raw parameters dialog:

- Decompression: OFF

- Initial byte offset: 0

- Sample Rate: Sample rate you recorded the samples at

- Channel: 2, quadrature

- Decode Format: 16 bit linear, little endian

When getting your bearings in the bladeRF-cli, it's handy to be able to visualize data while you're dialing in settings. Having external program show the samples RX'd by the bladeRF-cli comes in quite handy.

$ mkfifo /tmp/rx_samples.bin

Be sure to adjust samplerate and frequency parameters appropriately to ensure the display matches your hardware settings.

./baudline -reset -format le16 -channels 2 -quadrature -samplerate 2000000 -stdin < /tmp/rx_samples.bin

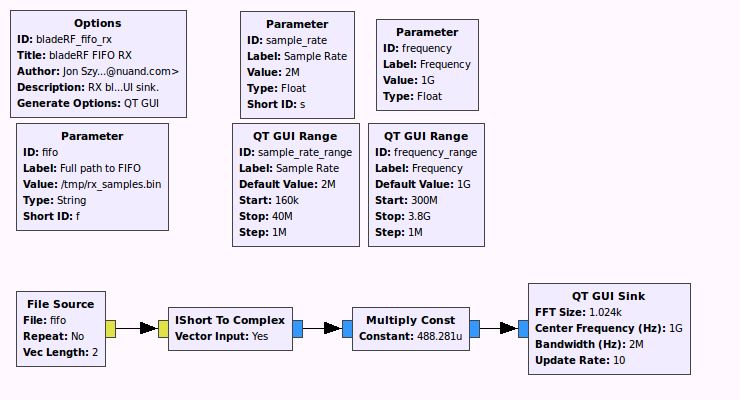

This flowgraph (python) converts bladeRF SC16 Q11 samples to GNU radio complex values and displays them with a Qt GUI sink. Note that the same conversion approach can be taken for transmitting.

./bladeRF_fifo_rx.py --sample-rate=2e6 --frequency=433.92e6

bladeRF> set frequency 433.92M bladeRF> set samplerate 2M bladeRF> set bandwidth 1.5M bladeRF> rx config file=/tmp/rx_samples.bin n=0 bladeRF> rx start bladeRF> # Adjust parameters while viewing the spectrum in baudline! bladeRF> rx stop

The bladeRF-cli provides the ability to transmit samples from either a binary or CSV SC16 Q11 file. It is generally very helpful during development/debugging stages to generate and write samples to a file, using one's language of choice, and then transmit them via the bladeRF-cli.

Run help tx from the CLI for a description of available parameters and other important notes.

This example shows how to use Octave or MATLAB to create samples for a simple sinusoids at +250 Khz, sampled at 2 Msps, and then transmit these sample with the bladeRF-cli. The same procedure here can be followed for your language of choice, provided you implement a few simple conversion routines.

Octave/MATLAB functions for loading/saving samples from/to the bladeRF SC16 Q11 binary and CSV formats are provided here in the bladeRF repository.

You can add these functions to your Octave/MATLAB path as follows:

>> addpath('~/projects/bladeRF/host/misc/matlab/');

help save_sc16q11

save_sc16q11 Write a normalized complex signal to a binary file in the

bladeRF "SC16 Q11" format.

[RET] = save_sc16q11(FILENAME, SIGNAL)

RET is 1 on success, and 0 on failure.

FILENAME is the target filename. The file will be overwritten if it

already exists. The file data is written in little-endian format.

SIGNAL is a complex signal with the real and imaginary components

within the range [-1.0, 1.0).Next, we create the signal:

% Our samples must be generated at the samplerate we plan to run the device at

SAMPLE_RATE = 2e6;

% Generate 10 seconds worth of samples. Bear in mind that when using the

% binary SC16 Q11 format, 1 sample consumes 4 bytes of memory/disk space.

% This quickly adds up - 10 seconds @ 2 Msps yields ~ 76.3 MiB. Be careful

% when using higher sample rates!

NUM_SECONDS = 10;

NUM_SAMPLES = NUM_SECONDS * SAMPLE_RATE;

% 250 kHz, in radians (ω = F_Hz * 2pi)

SIGNAL_FREQ_RAD = 250e3 * 2 * pi;

% Generate a vector "t" which represents time, in units of samples.

% This starts at t=0, and creates NUM_SAMPLES samples in steps of 1/SAMPLE_RATE

t = [ 0 : (1/SAMPLE_RATE) : (NUM_SECONDS - 1/SAMPLE_RATE) ];

% Create a sinusoid (signal = e^(jωt) ) with a magnitude of 0.90

signal = 0.90 * exp(1j * SIGNAL_FREQ_RAD * t);

% Plot the FFT of our signal as a quick sanity check.

% The NUM_SAMPLES denominator is just to normalize this for display purposes.

f = linspace(-0.5 * SAMPLE_RATE, 0.5 * SAMPLE_RATE, length(signal));

plot(f, 20*log10(abs(fftshift(fft(signal)))/NUM_SAMPLES));

xlabel('Frequency (Hz)');

ylabel('Power (dB)');

title('250 kHz tone');

% Save the signal to a file

save_sc16q11('/tmp/samples.sc16q11', signal); Here's an example of the expected plot:

It's generally recommended to save files to /tmp or a ramdisk location, rather than to a hard disk. For higher sample rates, reading samples from disk may cause underruns.

Next, we'll enter the bladeRF command line interface:

$ bladeRF-cli -i

bladeRF>First, we configure the device. Ensure the sample rate matches the rate the rate you created your samples with!

Note that the TXVGA1 and TXVGA2 gain values are dependent upon you're operating environment. You should start with setting these to low (e.g., TXVGA=1-20, TXVGA2=0) values if you're connecting directly to test equipment.

bladeRF> set frequency tx 925M

Set TX frequency: 925000000Hz

bladeRF> set samplerate tx 2M

Setting TX sample rate - req: 2000000 0/1Hz, actual: 2000000 0/1Hz

bladeRF> set bandwidth tx 1.5M

Set TX bandwidth - req: 1500000Hz actual: 1500000Hz

bladeRF> set txvga1 -10

bladeRF> set txvga2 0

bladeRF> set bandwidth tx 1.5M

Set TX bandwidth - req: 1500000Hz actual: 1500000Hz

bladeRF> set txvga1 -10

bladeRF> set txvga2 0Next, we configure the CLI to transmit out samples:

bladeRF> tx config file=/tmp/samples.sc16q11 format=binYou can also repeat the transmission of a file. For example, if you'd like to repeat the file the file 3 times, with a 1 second delay between each repetition:

bladeRF> tx config repeat=3 delay=1000000Now we'll transmit the file, and observe that it is running:

bladeRF> tx start

bladeRF> tx

State: Running

Last error: None

File: /tmp/samples.sc16q11

File format: SC16 Q11, Binary

Repetitions: 3

Repetition delay: 1000000 us

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000We can wait for the transmission to complete, via the tx wait command. This command will block until either the transmission completes or a specified timeout occurs. You can also interrupt this command with Ctrl-C.

bladeRF> tx wait

bladeRF> tx

State: Idle

Last error: None

File: /tmp/samples.sc16q11

File format: SC16 Q11, Binary

Repetitions: 3

Repetition delay: 1000000 us

# Buffers: 32

# Samples per buffer: 32768

# Transfers: 16

Timeout (ms): 1000The following screenshot from a VSA shows this tone being transmitted at the desired 250 kHz offset from the center frequency (925MHz). Note that this is from a device with its DC offset and IQ imbalance compensated for. See wiki page describing correction features if you see significant LO leakage at the center frequency, or a significant image at -250 kHz.

Currently, the following information is stored in a user-modifiable "calibration region":

- FPGA size (40 or 115)

- VCTCXO (Voltage-controlled temperature-compensated oscillator) trim DAC value

Unless you're planning to replace the FPGA (not a recommended endeavor), there's no reason to mess with this field. The reason the FPGA size is here rather than in the OTP region is largely historic and pertains to debug usage during early development and testing.

The VCTCXO frequency will drift over time and due to environmental factors. Users will generally want to periodically recalibrate the associated trim DAC value, and write it back to the bladeRF.

From with the bladeRF-cli's interactive mode, the current calibration values can be viewed via the info command:

bladeRF> info Serial #: 00000000000000000000000000000000 VCTCXO DAC calibration: 0xa0a8 FPGA size: 40 KLE FPGA loaded: no USB bus: 4 USB address: 2 USB speed: SuperSpeed Backend: libusb Instance: 0

Note the VCTXCO (trim) DAC calibration value above.

To back up this information to a file, which may later be restored through the bladeRF-cli program, the flash_backup command may be used. Type help flash_backup to see the full help text for this command.

The general usage for saving calibration data is flash_backup <output_file> cal:

bladeRF> flash_backup /home/jon/bladeRF-files/bladerf_cal_2014_03_18.bin cal [INFO] Reading 0x00000100 bytes from address 0x00030000.

This command will store the calibration data, along with some additional metadata, in the specified file. To view the associated metadata stored in the flash image, use the flash_image command. This metadata may prove useful if you've accidentally renamed a file, or forgot which device (via serial number) is associated with the file.

bladeRF> flash_image /home/jon/bladeRF-files/bladerf_cal_2014_03_18.bin Checksum: d3ad936733b841cd10f0cb852d2a133e08cf080a60c4a607cca9908b75bd5e59 Image format version: 0.1.0 Timestamp: 2014-03-18 20:25:37 Serial #: 00000000000000000000000000000000 Image type: Calibration data Address: 0x00030000 Length: 0x00000100

If you've backed up calibration data to a file via the flash_backup command, you can use the flash_restore command to write this data back to the device. Note that the serial number information in the metadata is strictly for informational purposes; it is not used to prevent data from being written to another device.

For more information about the flash_restore command, run help flash_restore.

bladeRF> flash_restore /home/jon/bladeRF-files/bladerf_cal_2014_03_18.bin [INFO] Reading 0x00010000 bytes from address 0x00030000. [INFO] Erasing 0x00010000 bytes starting at address 0x00030000. [INFO] Writing 0x00010000 bytes to address 0x00030000.

Note: A power cycle will be required for this change to take effect.

This approach useful if you'd like to manually specify a VCTCXO trim value to store in the device.

The flash_init_cal command generates a calibration region of flash, and can either write it directly to a device, or to a file (for future use with the flash_restore command).

For more information about this command, run help flash_init_cal from the bladeRF-cli interactive mode.

For a bladeRF with a 40 kLE FPGA and a desired VCTCXO trim DAC value of 0x9015, you can write this information directly to the device via:

bladeRF> flash_init_cal 40 0x9015 [INFO] Reading 0x00010000 bytes from address 0x00030000. [INFO] Erasing 0x00010000 bytes starting at address 0x00030000. [INFO] Writing 0x00010000 bytes to address 0x00030000.

Note: A power cycle will be required for this change to take effect.

Alternatively, to write this data to a file:

bladeRF> flash_init_cal 40 0x9015 /tmp/new_cal_data.bin

If you've managed to wipe your calibration region and do not have the necessary tools to identify an appropriate VCTCXO trim value, you may look up that factory default on this page.

bladeRF-cli -p returns 0 if one or more devices are detected, and a non-zero value if no devices are connected. Below is a snippet you can use to exit a script if no bladeRF devices are detected:

#!/bin/sh

bladeRF-cli -p 1>/dev/null 2>&1

if [ $? -ne 0 ]; then

echo "No bladeRF devices connected." >&2

exit 1

fi

The bladeRF-cli info command can be used to fetch a device's serial number or FPGA size, as shown below:

#!/bin/sh

# Fetch device information

DEVICE_INFO=$(bladeRF-cli -e 'info' 2>/dev/null)

if [ -z "$DEVICE_INFO" ]; then

echo "Failed to open device and query info." >&2

exit 1

fi

# Read a device's serial number

DEVICE_SERIAL=$(echo "$DEVICE_INFO" | grep 'Serial #:' | sed -e 's/.*Serial #:\s\+//')

# Check if the device has an FPGA loaded

DEVICE_FPGA_LOADED=$(echo "$DEVICE_INFO" | grep "FPGA loaded:" | sed -e 's/.*FPGA loaded:\s\+//')

# Read the device's FPGA size

DEVICE_FPGA_SIZE=$(echo "$DEVICE_INFO" | grep "FPGA size:" | sed -e 's/.*FPGA size:\s\+//')

echo ""

echo "Found bladeRF"

echo " Serial #: $DEVICE_SERIAL"

echo " FPGA type: $DEVICE_FPGA_SIZE"

echo " FPGA loaded: $DEVICE_FPGA_LOADED"

echo ""

When transmitting or receiving from a shell script, one must ensure rx wait or tx wait is used to ensure the CLI is not exited prior to the completing the desired reception/transmission.

Example: RX 10 seconds of data

bladeRF-cli -e 'rx config file=/tmp/rx_10s.bin n=0; rx start; rx; rx wait 10s'

Example: Transmit a file to completion

bladeRF-cli -e 'tx config file=/tmp/tx_samples.bin; tx start; tx; tx wait'

32 Pins are available for general use on the bladeRF's U74 expansion header. A subset of these pins are exposed for general use on the XB-200 Transverter and XB-100 Expansion boards.

Be careful with interacting with these pins -- they are directly connected to the 1.8V I/O pins on the FPGA. (Although some pins on the XB-200 are connected via a level translator.) Ensure you review the schematics and use appropriate buffers or level converters when attaching devices to these pins!

Support for manipulating these pins from a higher-level interface was introduced on September 1st, 2015. You'll need to be using a version of libbladeRF, the bladeRF-cli, and an FPGA image (>= v0.4.1) from this commit or later.

First, run the following commands to view the help and usage information for each.

bladeRF> print xb_gpio bladeRF> print xb_gpio_dir bladeRF> set xb_gpio bladeRF> set xb_gpio_dir

As described above, we can print the state of expansion I/O pins:

bladeRF> print xb_gpio_dir all

Expansion GPIO direction register: 0x00000000

GPIO_1: input

GPIO_2: input

GPIO_3: input

GPIO_4: input

GPIO_5: input

GPIO_6: input

GPIO_7: input

GPIO_8: input

GPIO_9: input

GPIO_10: input

GPIO_11: input

GPIO_12: input

GPIO_13: input

GPIO_14: input

GPIO_15: input

GPIO_16: input

GPIO_17: input

GPIO_18: input

GPIO_19: input

GPIO_20: input

GPIO_21: input

GPIO_22: input

GPIO_23: input

GPIO_24: input

GPIO_25: input

GPIO_26: input

GPIO_27: input

GPIO_28: input

GPIO_29: input

GPIO_30: input

GPIO_31: input

GPIO_32: input

bladeRF> print xb_gpio all

Expansion GPIO register: 0xffffffff

GPIO_1: 1

GPIO_2: 1

GPIO_3: 1

GPIO_4: 1

GPIO_5: 1

GPIO_6: 1

GPIO_7: 1

GPIO_8: 1

GPIO_9: 1

GPIO_10: 1

GPIO_11: 1

GPIO_12: 1

GPIO_13: 1

GPIO_14: 1

GPIO_15: 1

GPIO_16: 1

GPIO_17: 1

GPIO_18: 1

GPIO_19: 1

GPIO_20: 1

GPIO_21: 1

GPIO_22: 1

GPIO_23: 1

GPIO_24: 1

GPIO_25: 1

GPIO_26: 1

GPIO_27: 1

GPIO_28: 1

GPIO_29: 1

GPIO_30: 1

GPIO_31: 1

GPIO_32: 1

Note that since neither the XB-200 or XB-100 is attached, the pin names are presented as they pertain to the U74 connector on the bladeRF board.

If an expansion board has been enabled via xb 100 enable or xb 200 enable, then only the available I/O pins will be listed. Additionally, the pins names will reflect their associated item on the board.

The first example shows how to toggle pin 6 on header J7 of the XB-200 Transverter board.

bladeRF> xb 200 enable

Enabling XB-200 transverter board

XB-200 Transverter board successfully enabled

bladeRF> print xb_gpio all

Expansion GPIO register: 0xffffcfe9

J7_1: 1

J7_2: 1

J7_6: 1

J13_1: 1

J13_2: 1

J16_1: 1

J16_2: 1

J16_3: 1

J16_4: 1

J16_5: 1

J16_6: 1

bladeRF> print xb_gpio_dir all

Expansion GPIO direction register: 0x3c00383e

J7_1: input

J7_2: input

J7_6: input

J13_1: input

J13_2: input

J16_1: input

J16_2: input

J16_3: input

J16_4: input

J16_5: input

J16_6: input

bladeRF> set xb_gpio_dir J7_6 output

J7_6: output

bladeRF> print xb_gpio J7_6

J7_6: 1

bladeRF> set xb_gpio J7_6 0

J7_6: 0

bladeRF> set xb_gpio J7_6 1

J7_6: 1

When following the above, you'll see J7 pin 6 change from 1.8V to 0V, and then back to 1.8V.

The next examples shows how to toggle one of the colors in the RGB LED on the XB-100 expansion board. On the current revision of these boards, voltage on the FPGA I/O pins (LED cathode) is not high enough to turn off LEDs on the XB-100. As a workaround, set the LED pin's value to '1' and toggle its direction between 'input' and 'output' to turn the LEDs "off" and "on," respectively.

bladeRF> xb 100 enable

Enabling XB-100 GPIO expansion board

XB-100 GPIO expansion board successfully enabled

bladeRF> print xb_gpio all

Expansion GPIO register: 0xf9ff01bb

J2_3: 0

J2_4: 1

J3_3: 1

J3_4: 0

J4_3: 0

J4_4: 0

J5_3: 0

J5_4: 0

J11_2: 1

J11_3: 1

J11_4: 0

J11_5: 1

J12_5: 1

LED_D1: 1

LED_D2: 1

LED_D3: 1

LED_D4: 1

LED_D5: 1

LED_D6: 1

LED_D7: 1

LED_D8: 1

TLED_RED: 1

TLED_GREEN: 1

TLED_BLUE: 1

DIP_SW1: 0

DIP_SW2: 0

DIP_SW3: 0

DIP_SW4: 0

BTN_J6: 1

BTN_J7: 1

BTN_J8: 1

bladeRF> print xb_gpio_dir all

Expansion GPIO direction register: 0xf9f80000

J2_3: input

J2_4: input

J3_3: input

J3_4: input

J4_3: input

J4_4: input

J5_3: input

J5_4: input

J11_2: input

J11_3: input

J11_4: input

J11_5: input

J12_5: input

LED_D1: output

LED_D2: output

LED_D3: output

LED_D4: output

LED_D5: output

LED_D6: output

LED_D7: output

LED_D8: output

TLED_RED: output

TLED_GREEN: output

TLED_BLUE: output

DIP_SW1: input

DIP_SW2: input

DIP_SW3: input

DIP_SW4: input

BTN_J6: input

BTN_J7: input

BTN_J8: input

bladeRF> set xb_gpio_dir TLED_RED input

TLED_RED: input

bladeRF> set xb_gpio_dir TLED_RED output

TLED_RED: output

bladeRF> set xb_gpio_dir TLED_RED input

TLED_RED: input

If you've built bladeRF-cli with support for libtecla (highly recommended), you'll have a number of great features available to you, including history, tab-completion (for filenames) and handy key bindings (including emacs and vi bindings).

See the tecla man page for detailed information about configuring and using libtelca-based programs.

To use vi or emacs key bindings, create a ~/.teclarc file, and add the relevant line:

edit-mode vior

edit-mode emacs

WIP, basically the SMB port acts as an input or output, but not both simultaneously.

The bladeRF-micro features a dual-input clock buffer that can select either the on-board VCTCXO, or an external 38.4 MHz clock to be fanned out to the various components on the board. The on-board VCTCXO is selected by default.

Certain applications (e.g. MIMO, RADAR, etc.) may require multiple bladeRFs to be synchronized using the exact same clock source. For best results, an external clock distribution network with matched cables is used so the frequency and phase differences between each board is as close to zero as possible. The bladeRF2-micro can receive such an external clock using the U.FL port labeled, CLKIN (U93). The external clock must be 38.4 MHz and 3.3 V CMOS logic.

It is important to note that the FX3 requires the clock to be within 150 ppm (5 kHz) of its ideal frequency of 38.4 MHz. While Nuand has been able to deviate by as much as 100 kHz before experiencing stability issues, it is recommended to stay as close to 38.4 MHz as possible due to temperature and process variations.

Using the bladeRF-cli, select the external clock input port:

bladeRF> set clock_sel external

Clock input: External via CLKINTo return to the onboard VCTCXO:

bladeRF> set clock_sel onboard

Clock input: Onboard VCTCXOTo view the clock selection at any time:

bladeRF> print clock_sel

Clock input: Onboard VCTCXOWIP, basically the SMB port acts as an input or output, but not both simultaneously.

One of the outputs of the bladeRF2-micro clock buffer is connected to an external U.FL port labeled CLKOUT (U92). This may be used to supply a 38.4 MHz, 3.3 V CMOS clock to other devices. This output may be enabled or disabled using the bladeRF-cli:

bladeRF> set clock_out enable

Clock output: Enabled via CLKOUT

bladeRF> set clock_out disable

Clock output: Disabled

bladeRF> print clock_out

Clock output: DisabledThe print command of bladeRF-cli has been updated to include a hardware convenience parameter that groups what would otherwise be multiple status commands into a single command. Currently, only the bladeRF2-micro has this hardware group, but it will eventually include the bladeRF Classic.

An example usage of this command is shown below for a bladeRF2-micro.

bladeRF> print hardware

Hardware status:

RFIC status:

Temperature: 19.3 °C

CTRL_OUT: 0xf8 (0x035=0x00, 0x036=0xff)

Power source: USB Bus

Power monitor: 4.78 V, 0.6 A, 2.88 W

RF switch config:

TX1: RFIC 0x0 (TXA ) => SW 0x0 (OPEN )

TX2: RFIC 0x0 (TXA ) => SW 0x0 (OPEN )

RX1: RFIC 0x0 (A_BAL ) <= SW 0x0 (OPEN )

RX2: RFIC 0x0 (A_BAL ) <= SW 0x0 (OPEN )Under the RFIC status section, there is a temperature readout and a status of the CTRL_OUT pins. The RFIC used on the bladeRF-micro has an on-chip thermocouple allowing it to measure the die temperature. The CTRL_OUT pins are a set of eight real-time status outputs that can be configured to represent many different options, as dictated by the AD9361 RFIC's register contents at addresses 0x035 and 0x036. To view the available options, review the AD9361 Reference Manual (UG-570).

The power source is reported by the on-board automatic power multiplexer. The device above was using USB power at the time of the reading, but DC barrel power would be reported as such.

The bladeRF2-micro also has a power sensor module that reports instantaneous voltage, current, and power on the main 5 V rail.

Finally, the print hardware command will report the RF switch configuration. The RFIC on the bladeRF2-micro has two TX channels and two RX channels (2R2T MIMO). Each RX channel has three band selection options (A, B, and C), and each TX channel has two band selection options (A and B). An external RF switch is used to select which band is active on the SMA port.

The bladeRF-cli allows the user to specify the device to open by passing a device string with the -d <device_string> option. The format of device_string is outlined in the bladerf_open() section of the libbladeRF API.

When multiple bladeRFs are used, it is often very useful to specify the serial number of the desired board to use when opening bladeRF-cli. For example, to open serial number 1337...beef using any available backend, the following command may be used. Note that the full serial number is not required; only the first few digits to (reasonably) ensure its uniqueness.

$ bladeRF-cli -d "*:serial=1337" -e version

bladeRF-cli version: 1.6.1-git-911387a3-dirty

libbladeRF version: 2.0.1-git-911387a3-dirty

Firmware version: 2.2.0-git-4bcdd6ec

FPGA version: Unknown (FPGA not loaded)